History of Trexler Balloon Wheels

In 1935 Bill Trexler was 42 years old and Plant Superintendent at the Oak Rubber Company in Ravenna, when he got his idea for a special type of inflatable model airplane tire. Oak Rubber manufactured millions of toy balloons and was for decades the largest manufacturer of toy balloons in the world.

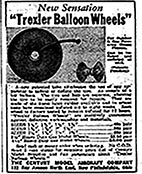

Bill had seen other inflatable rubber model airplane tires, but they all had some type of problem with the valves that hold the air inside, plus they were expensive. Generally, the tire valves were cumbersome, complicated, and expensive to make. Being intimately familiar with the dipping process, Bill developed the idea of a simple integral valve stem that could be molded with the tire during manufacture to reduce cost. This rubber stem was then twisted and tucked between the tire and the wood hub during use, the pressure of the inflated tire against the wood hub scaled the flexible valve until it was pulled free. The simplicity of this design allowed him to sell the tires for less than the competition. During the Depression this was a major sales advantage.

Oak Rubber encouraged Bill to seek a design patent, and with the help of the American Anode Company (later part of B.F. Goodrich) in nearby Akron, a patent was applied for and granted for his tire and valve design. At the time Akron was known as 'The Rubber Capital of the World" and was home to Goodrich, Goodyear, Firestone, General, and a host of smaller independent rubber companies.

American Anode facilitated in the project because they owned the rights to the recently developed "Anode" latex rubber dipping process by which the tires were to be made. They had been instrumental in developing this water based dipping process which is totally unlike the manufacture of auto tires which are molded at high pressure and temperature. Anode (and later Goodrich) assisted many inventors with ideas relating to the development of dipped rubber goods, they would then license their manufacturing process for manufacture of these goods. Today the latex dipping process is used primarily in the medical field where millions of surgeon's gloves and condoms are made every day.

Mr. Trexler began the manufacture of tires in the basement of his home in Ravenna, but soon the smell of the rubber and demands of production (and his wife Caroline) required that he move the operation to a small shop behind his house. Here the business continued to grow and he began the manufacture of other specialty rubber products, which were "small runs", or low-volume items which Oak Rubber could not produce efficiently. During WWII he manufactured several special military items for the defense department on his own while turning out thousands of military weather balloons and rubber raincoats at Oak. After the war he was approached by the Louis Marx toy company to manufacture special rubber diapers for a small wind-up baby doll the company was going to introduce. They struck a deal and production began in earnest on thousands of the rubber toy diapers. Soon the demand for these and other specialty rubber products in both industrial and consumer goods outstripped his own capacity and he decided to expand the company's production. In 1953 he incorporated the business as the Trexler Rubber Company and built a new factory.

Trexler Rubber went on to manufacture thousands of specialty dipped rubber products over the next 40 years, from items as simple as rubber pouting spouts for glass milk bottles to custom designed items for NASA. In the 1960s Trexler produced parts for the astronauts' space suits that were used in the Gemini spacewalk missions. Today Trexler produces special rubber products for industrial, medical, veterinary, and prototype work for customers around the world. The natural rubber products they make range in size from a small thimble to rubber bags the size of a compact car. These rubber products are the largest monolithic dipped rubber products in the world. Through all this expansion Mr. Trexler continued to make and ship his balloon tires which he watched over during his daily rounds. He was actively involved his company well into his 90s and still enjoyed "talking shop" until he died in 1991 at the age of 96.

Today the company is still family owned and operated by his grandson, Tom Trexler. Though balloon tires are only a tiny fraction of the business today, Trexler continues to offer specialized design and manufacturing services to their loyal customers worldwide.