Instructions for Trexler Balloon Wheels

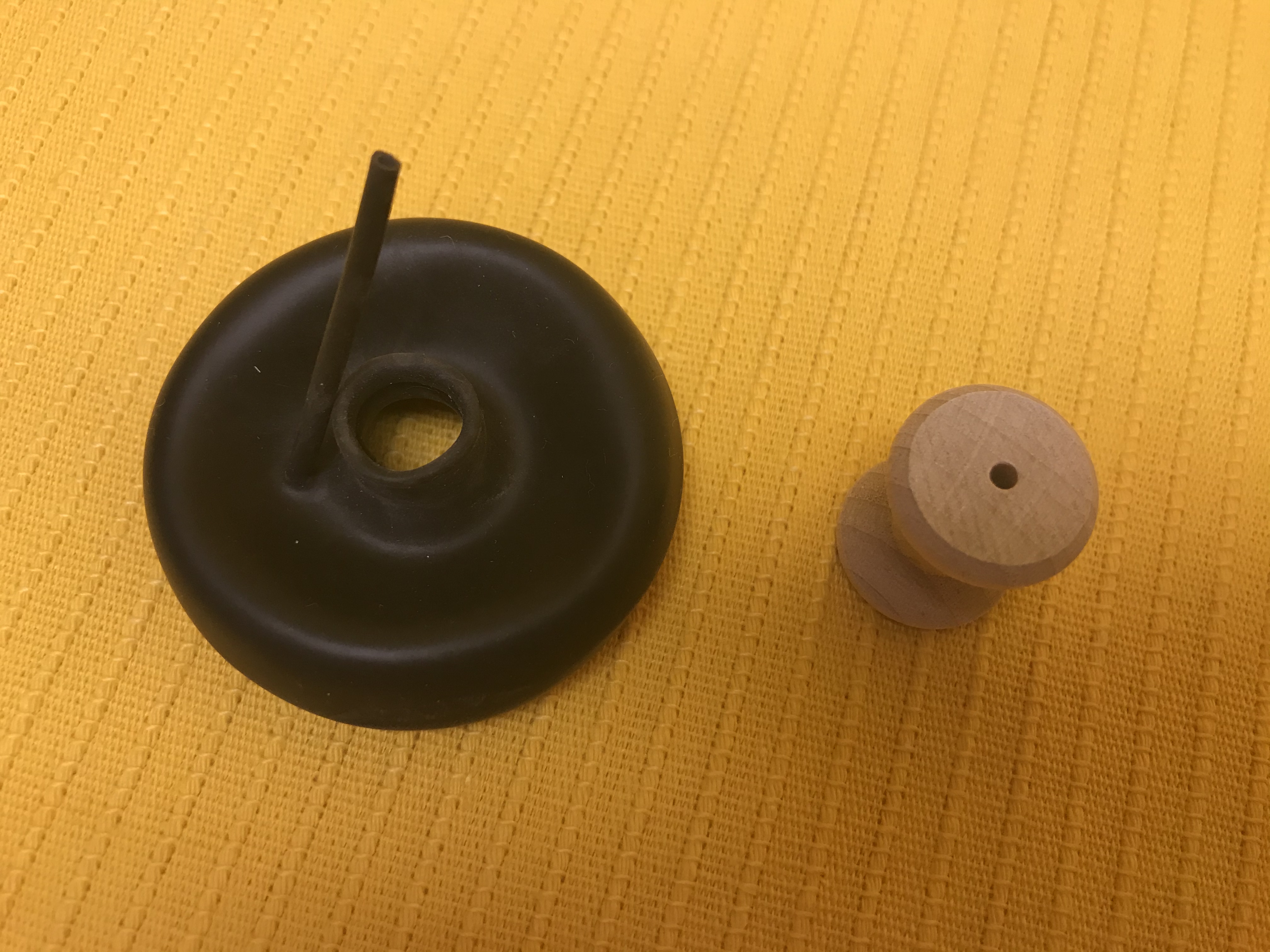

Trexler Balloon Wheels for model airplanes can be inflated by the patented (US#2,206,438) tube on each wheel.

The wheel and hub are separate, allowing the wheel to be easily removed for repairs. Wheels are made of the finest latex available. Because inflating Trexler Balloon Wheels is so simple, they are shipped directly from the factory deflated. This assures full life to the purchaser. Each pair of wheels is packed in an individual box, with size plainly marked, and with the instruction sheet enclosed.

To Inflate and Deflate:

With each Trexler Balloon Wheel there is a tube attached to inflate and deflate. Care should be taken not to inflate the wheel larger than the size stamped on the carton.

After the wheel is inflated to the correct size, simply wind the valve stem around the hub to within 1/2" of the end, then twist and tuck the end between the hub and tire. Care should be taken not to allow any moisture in the tube, suggesting the use of a small hand pump rather than breath.

Storing tires in relaxed, deflated position and protected from ozone is recommended.

Customizing Hub:

Remove tire from hub being careful to protect latex from puncture. Allow paint to dry before reinstalling wheel.

To Make Wheels Perfectly Round:

Push the large side of the wheel around the hub after inflating.

To Eliminate Any Side Wobble:

Push the wheel sideways into proper alignment on the hub.