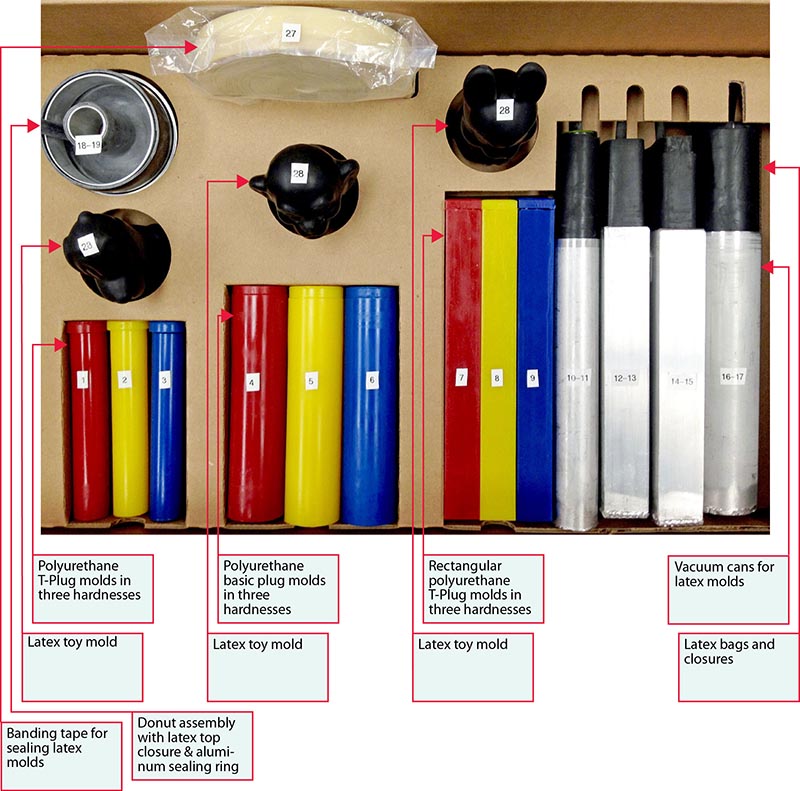

The Trexler Rubber Isostatic Molding Experimental Kit allows you to try various isostatic pressing techniques on your powder. The experimental kit contains:

- 9 Polyurethane bags with plugs

- 4 Rubber bags with closures, containers and vacuum can

- 42 Balloon bags, assorted sizes

- Miscellaneous other supplies

The rubber bag is placed in the perforated aluminum container and filled with powder. The sealing ring is inserted and then the rubber top closure. The neck of the bag is wrapped and tied securely with banding tape so no liquid or air can seep into the bag during pressing.

The powder-filled bag, sealed inside its supporting aluminum container, is placed into the press. As the pressure is raised to the required level, the powder is compressed into the desired form.

After the pressing cycle is completed, the entire assembly is removed from the isostatic press. The pressed part is removed and is now ready for its finishing process.

Isostatic Molding Example

The brief description below of isostatic pressing is only an introduction. Please contact us for additional information.

A rubber bag holds the powdered material. The top closure shown here has an optional de-airing tube and is urethane filled to allow firm structure for sealing bag tight against closure.

Aluminum support container surrounds bag for shape during powder fill and pressing. Holes in bottom of container provide drainage of press fluid.

Bag being removed from container following pressing.